Automated warehouse: Achieving automation in transportation.

Realization of automatic transport from the manufacturing site to the product and parts management process.

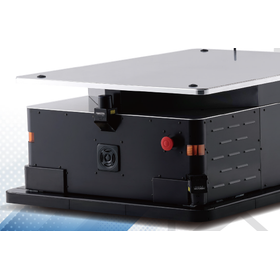

<Achieving Automatic Transportation from Manufacturing Sites to Product and Parts Management Processes> - Significant reduction in labor hours through automation of inbound and outbound processes By predicting parts shortages on the production line in advance, the downtime of the production line can be shortened, allowing for improved operational efficiency. - Promotion of DX (Digital Transformation) at each layer In addition to improving operational efficiency at the "machine level," such as reducing downtime, understanding necessary inventory levels and order quantities can enhance productivity at the "line and factory level." Furthermore, integration with core systems like ERP and MES is possible. We promote the DX of parts management processes at each layer, enabling a reduction in management labor hours. <Case Study Introduction> ◇Before The distance to the warehouse places a heavy burden on workers. We want workers to handle various tasks. Transportation of parts requires a lot of manpower. ◇After We were able to achieve automatic transportation with AGVs. By reducing work time, workers can now engage in other tasks. <Related Products> Automated Warehouse ISM Series Automated Transport Robot - Autonomous Mobile Robot *For more details, please refer to the PDF materials or feel free to contact us.

- Company:JUKI

- Price:Other

![Nabe Shimizu Glory Co., Ltd. [Case Study on the Introduction of Automated Guided Vehicles (AGV)]](https://image.www.ipros.com/public/product/image/f36/2001101846/IPROS97408844946836141772.png?w=280&h=280)

![Unmanned Automated Transport Robot 'Σone100' [Capable of carrying up to 400kg]](https://image.www.ipros.com/public/product/image/5dd/2001013254/IPROS34813833567115220145.png?w=280&h=280)

![[Information] Introduction to AMR/AGV/AGF Products](https://image.www.ipros.com/public/product/image/2103284/IPROS17829383314915718931.png?w=280&h=280)

![[PPS Case] AGV-Linked Sorting Solution](https://image.www.ipros.com/public/product/image/095/2000610331/IPROS78462107724503822071.png?w=280&h=280)